With nearly 5 decades of years of experience, Marcus offers versatile die-casting solutions with focus on quality, seamless delivery and lowest lead times.

With nearly 5 decades of years of experience, Marcus offers versatile die-casting solutions with focus on quality, seamless delivery and lowest lead times.

Oversized Units, Narrow Sightliness, Limitless custom solutions. Our highly skilled team ensures the finest products with high precision.

With nearly 5 decades of years of experience, Marcus offers versatile die-casting solutions with focus on quality, seamless delivery and lowest lead times.

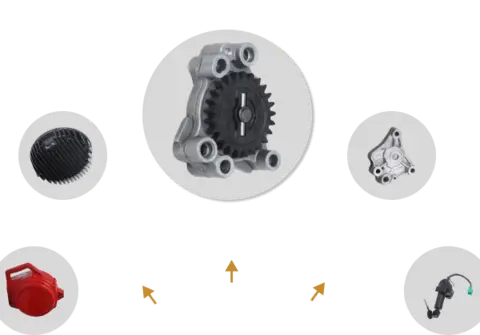

We offer a wide range of products and services for your project needs. Choose a category and let’s get started.

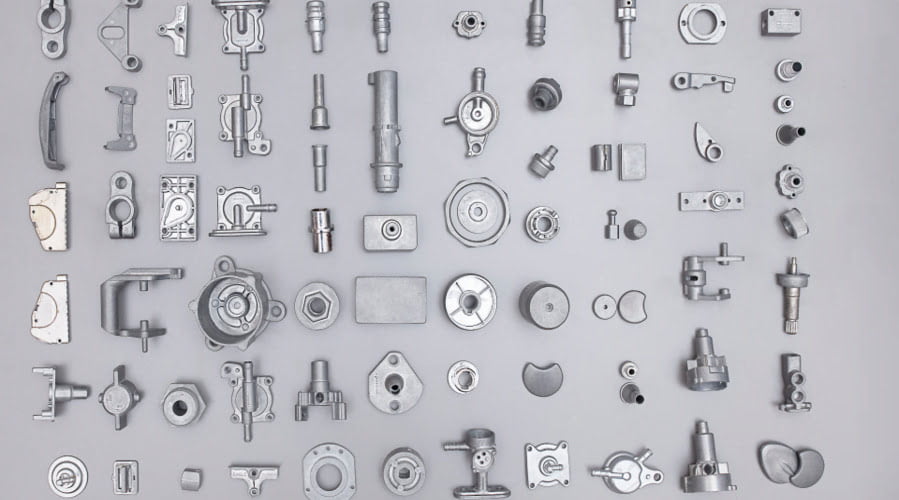

Established in 1980, Marcus Hi-tech Engineering, an IATF Certified Company is a global manufacturer of die-casting solutions specializing in Zinc, Aluminum, and Lead casting.

Established in 1980, Marcus Hi-tech Engineering, an IATF Certified Company is a global manufacturer of die-casting solutions specializing in Zinc, Aluminum, and Lead casting.

Manufacturing world-class parts & products.

We ensure superior quality for products across Industries.

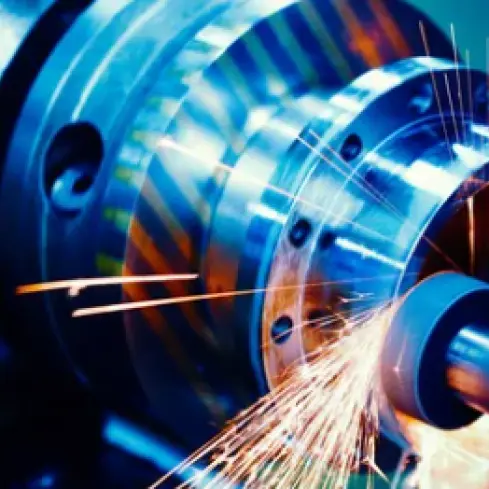

Marcus Hi-Tech Engineering offers complete agile manufacturing solutions. Our well-equipped manufacturing units and in-house tool room facilities enable us to produce high-quality, precision products within given timelines

We offer a wide range of products and services for your project needs. Choose a category and let's get started.

Lowest Lead Time

Precision Machining

Superior Finishing

With our 20 CNC machines and 17 Die casting machines, we enable brands to manufacture products at every scale.

The team Marcus consists of industries top professionals and vetted engineers. Our expertise and experience solves complex challenges with innovation and excellence.

Post customer raises an inquiry, our tested and trusted process sets up the benchmark for industry. Facilitating company’ vision, we continuously invests in human resources and machining equipments.

From consulting our customers to choose right solutions to going through strict quality control measures, our goal is to achieve 100% customer satisfaction. Every new customer is our partner for growth.

Marcus is a leading exporter of die castings and industrial products to global brands.

Explore Expert Perspectives About Die-Casting Industry

Die casting is a manufacturing process where high-pressure forces molten metal into a mold cavity. The metal cools and solidifies, taking the shape of the mold. The mold is then opened, and the newly formed metal part is ejected.

Several finishing options are available for die-cast parts, including painting, plating, anodizing, and powder coating. These finishing options can help improve the appearance and durability of the parts and provide additional protection against corrosion and wear.

Marcus has a comprehensive quality control system in place to ensure that all parts produced meet or exceed customer requirements. This includes rigorous testing and inspection throughout the production process and ongoing monitoring and evaluation of quality metrics.

Yes, Marcus can provide custom tooling for die-casting projects. The company has in-house tooling capabilities and can work with customers to design and manufacture custom molds and tooling to meet their specific needs.

Marcus offers a range of design support services for die-casting projects, including design for manufacturability (DFM) analysis, 3D modeling, and prototyping. The company’s team of experienced engineers can work with customers to optimize their designs for the die-casting process and ensure that parts can be produced efficiently and effectively.

With over 4 decades of experience and crafting products for 100+ brands, we are the perfect partner for die casting.

Check out our newest details

Tell us your query in detail.