India’s pressure die casting industry has experienced a remarkable surge, positioning itself as a powerhouse in the global market. With a combination of technological advancements, a skilled workforce, and favorable government initiatives, the industry presents many possibilities for domestic and international stakeholders. According to estimates, the High-pressure Die Casting Market will be worth USD 36.42 billion in 2023 and is predicted to grow at a CAGR of 6.16% until 2028, reaching a value of USD 49.11 billion.

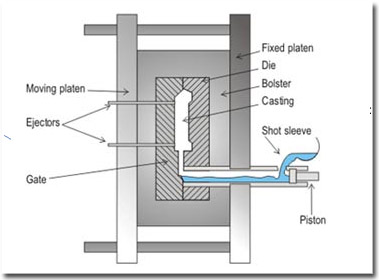

The pressure die casting process, known for its ability to produce intricate and precise components, has become a critical manufacturing technique across various industries. This process involves injecting molten metal, such as aluminum, zinc, or magnesium, into a high-pressure mold, creating complex and dimensionally accurate parts.

The demand for pressure die casting components has been steadily rising, driven by the need for lightweight and high-quality products in industries such as automotive, aerospace, electronics, and consumer goods. Technological advancements have been instrumental in shaping the growth of India’s pressure die casting industry. Automation, robotics, and advanced control systems have revolutionized manufacturing, leading to increased productivity, improved product consistency, and reduced material waste.

Industry 4.0 technologies like IoT and data analytics have boosted India’s pressure die casting industry. The government’s policies and initiatives, including Make in India and infrastructure development, have helped the sector grow. In this article, we’ll explore the industry’s trends, benefits, and opportunities and how government initiatives have played a role in its expansion.

The Rise of Pressure Die Casting in India

Technological Advancements

Technological advancements have played a crucial role in India’s rise in pressure die casting. Adopting advanced machinery, automation, and digitalization have enhanced productivity, efficiency, and quality in the manufacturing process. Modern die casting machines equipped with robotics, sensors, and sophisticated control systems have revolutionized production, reducing cycle times and minimizing errors.

Furthermore, implementing Internet of Things (IoT) devices and real-time data analytics has enabled remote monitoring, predictive maintenance, and process optimization.

Skilled Workforce

India’s abundant skilled workforce has significantly contributed to the rise of the pressure die casting industry. The country’s solid educational infrastructure and emphasis on technical education have produced talented engineers, technicians, and operators proficient in die casting technologies. The availability of skilled professionals in areas such as tool and die design, process optimization, quality control, and metallurgy has facilitated the industry’s growth. The expertise and adaptability of the Indian workforce have been instrumental in meeting the industry’s evolving demands and maintaining high-quality standards.

Growing End-Use Industries

The growing demand from different industries is driving the increase in pressure die casting in India. The automotive sector, is a significant contributor to this trend. Pressure die casting is a vital process in the automotive manufacturing supply chain.

Industries such as aerospace, electronics, telecommunications, and consumer goods have also witnessed a growing reliance on pressure die casting. With its stringent quality and performance standards, the aerospace sector relies on die cast components for aircraft structures, engine parts, and interior fittings. The electronics industry, driven by technological advancements, requires intricate and compact details that can be efficiently produced through pressure die casting.

Favorable Government Initiatives

The Indian government has taken proactive measures to promote the growth of the manufacturing sector, including pressure die casting. Initiatives such as Make in India, aimed at boosting domestic manufacturing and attracting foreign investment, have created a favorable business environment for the industry. The government’s focus on improving the ease of doing business, providing infrastructure support, and implementing policies to encourage innovation and skill development has further catalyzed the rise of pressure die casting in India.

As demand for top-quality components grows, this sector is expected to offer profitable opportunities. Stay tuned for the latest trends and benefits of investing in this prosperous industry.

Material Innovation

Innovation in materials has played a crucial role in shaping the pressure die casting industry in India. Developing high-performance alloys with improved mechanical properties, such as enhanced strength-to-weight ratios and superior corrosion resistance, has opened up new possibilities for diverse applications. Moreover, using recyclable materials aligns with sustainable practices and helps reduce the industry’s environmental footprint.

Popular Trends in the Pressure Die Casting Industry

Lightweight and Complex Component Designs

One of the prominent trends in the pressure die casting industry is the increasing demand for lightweight and complex component designs. With an emphasis on fuel efficiency, reduced emissions, and enhanced performance, industries such as automotive and aerospace require lightweight materials without compromising strength and durability.

Pressure die casting, with its ability to produce intricate and lightweight components, has become a preferred choice for manufacturers. The trend towards using aluminum and magnesium alloys, known for their lightweight properties, is driving innovation in die casting processes and material development.

Enhanced Surface Finishes and Aesthetics

As consumer preferences evolve, there is a growing emphasis on enhanced surface finishes and aesthetics in pressure die casting. Manufacturers are investing in advanced surface treatment techniques, such as shot blasting, polishing, and powder coating, to achieve superior finishes and textures.

This trend is particularly relevant in industries like consumer electronics and home appliances, where visual appeal and product aesthetics play a crucial role in customer satisfaction. Pressure die casting allows for the precise replication of complex designs, resulting in visually appealing and high-quality surface finishes.

Sustainable Die Casting Practices

Sustainability is a crucial focus in the pressure die casting industry. Manufacturers are adopting sustainable practices to reduce environmental impact and improve resource efficiency. This includes implementing energy-efficient machinery, optimizing production processes to minimize material waste, and promoting recycling and reusability of die casting materials.

The use of eco-friendly die lubricants, water-based release agents, and advanced filtration systems to minimize emissions and waste generation is also gaining traction. As environmental regulations become more stringent, sustainable die casting practices will continue to be a significant trend in the industry.

Integration of Additive Manufacturing

The integration of additive manufacturing, commonly known as 3D printing, with pressure die casting is an emerging trend that offers significant benefits. Additive manufacturing allows for the production of intricate and customized molds with complex geometries that are challenging to achieve through traditional methods.

By combining the design flexibility of additive manufacturing with the efficiency and scalability of pressure die casting, manufacturers can reduce lead times, enhance product customization, and optimize the overall manufacturing process. This integration also enables rapid prototyping, minimizing costs and time associated with traditional tooling.

Digitalization and Industry 4.0 Technologies

Digitalization and the adoption of Industry 4.0 technologies are transforming the pressure die casting industry. Implementing IoT devices, real-time monitoring systems, and data analytics enables predictive maintenance, remote diagnostics, and process optimization.

Machine learning and artificial intelligence are being employed to analyze data and optimize process parameters, leading to improved efficiency, reduced downtime, and enhanced product quality. Integrating digital technologies and automation streamlines operations enables faster decision-making, and increases overall productivity.

These trends are reshaping India’s pressure die casting industry, opening up new opportunities for manufacturers and driving innovation. In the following sections, we will explore the opportunities available in the Indian pressure die casting sector and the advantages of investing in this thriving industry.

Growing Demand and Industry-Wise Opportunities for the Pressure Die Casting Industry in India

Automotive Industry

The automotive industry in India is witnessing robust growth, presenting significant opportunities for the pressure die casting sector. With the increasing demand for lightweight and fuel-efficient vehicles, pressure die casting plays a crucial role in manufacturing engine components, transmission parts, suspension systems, and other critical automotive components. The industry’s shift towards electric and hybrid vehicles further amplifies the demand for die cast aluminum components, such as motor housings and battery casings. By catering to the automotive industry’s evolving needs, the pressure die casting sector can capitalize on the growth opportunities and forge strong partnerships with automotive manufacturers.

Aerospace and Defense Sector

India’s aerospace and defense sector is experiencing remarkable growth, opening doors for the pressure die casting industry. The sector demands high-performance components that are lightweight, structurally sound, and capable of withstanding extreme conditions. Pressure die casting facilitates the production of intricate aerospace components like turbine blades, engine casings, brackets, and structural parts.

As India strives to enhance its domestic aerospace manufacturing capabilities and attract global partnerships, the pressure die casting industry can contribute significantly by delivering high-quality precision components and meeting the stringent requirements of the aerospace and defense sector.

Electronics and Telecommunications

The electronics and telecommunications industries present lucrative opportunities for India’s pressure die casting industry. With the rapid advancement of technology and the increasing demand for smaller, lightweight, and complex components, pressure die casting offers a cost-effective solution. The industry relies on die cast parts for smartphones, laptops, tablets, networking equipment, and consumer electronics. As the demand for these devices continues to rise, the pressure die casting sector can cater to the electronics and telecommunications industry by providing high-quality die cast components with superior surface finishes and tight tolerances.

Industrial and General Engineering

The industrial and general engineering sectors provide a broad range of opportunities for the pressure die casting industry. From machinery and equipment manufacturing to infrastructure development, these industries require precision components that are durable, dimensionally accurate, and capable of withstanding demanding conditions.

Pressure die casting can supply critical components like pump housings, valves, hydraulic and pneumatic components, and structural parts for various industrial applications. By catering to the diverse needs of the industrial and general engineering sectors, the pressure die casting industry can establish solid partnerships and contribute to the growth of these industries.

Consumer Goods

The consumer goods industry presents another avenue of growth for India’s pressure die casting sector. With the rising demand for aesthetically appealing and high-quality products, pressure die casting plays a vital role in manufacturing components for appliances, home decor, furniture, and other consumer goods. Die cast parts offer versatility in design, ensuring intricate shapes, precise dimensions, and superior surface finishes.

By capitalizing on the growing consumer goods market, the pressure die casting industry can establish itself as a reliable supplier of premium quality components to leading consumer goods manufacturers.

By tapping into these industry-wise opportunities and aligning with the specific demands of each sector, the pressure die casting industry in India can leverage its strengths, technological advancements, and skilled workforce to fuel its growth and establish a strong foothold in the domestic and global markets.

Advantages of Investing in India’s Pressure Die Casting Industry

- Export Potential: India’s pressure die casting industry has substantial export potential. Its high-quality components at competitive prices have attracted international markets. Indian manufacturers have secured contracts by meeting global quality standards, leading to more export opportunities.

- Export Potential: India’s pressure die casting industry has substantial export potential. Its high-quality components at competitive prices have attracted international markets. Indian manufacturers have secured contracts by meeting global quality standards, leading to more export opportunities.

- Skills: India boasts a large pool of experienced professionals in engineering, tool and die design, process optimization, and quality control. The availability of a talented workforce enables manufacturers to meet the demands of complex die casting projects and stay competitive in the global market.

- Skills: India boasts a large pool of experienced professionals in engineering, tool and die design, process optimization, and quality control. The availability of a talented workforce enables manufacturers to meet the demands of complex die casting projects and stay competitive in the global market.

- Favorable Government Initiatives: India has implemented initiatives to support manufacturing, like Make in India and policy changes. Industrial corridors such as DMIC are profitable for pressure die casting industry growth.

- Favorable Government Initiatives: India has implemented initiatives to support manufacturing, like Make in India and policy changes. Industrial corridors such as DMIC are profitable for pressure die casting industry growth.

Also Check: A Comprehensive Guide to High-Pressure Die Casting

Final Words

If chosen wisely, the right pressure die casting manufacturers can make large-scale industrial projects successful by producing high-quality components. With advancements in technology, a skilled workforce, diverse end-use industries, and supportive government initiatives, India has established itself as a competitive player in the global die casting market.

By capitalizing on these trends and opportunities, stakeholders can pave the way for a prosperous future in India’s pressure die casting industry.