Marcus boasts 40+ years of experience in high-pressure die casting and precision manufacturing solutions. We deliver top-quality die-cast with unmatched precision and efficiency with the latest manufacturing technology and machinery.

High-Pressure Die Casting (HPDC) is a highly efficient and cost-effective method of manufacturing high-quality metal parts for large-volume production. The process can produce parts with tight dimensional tolerances, excellent surface finishes, and intricate geometries. Marcus specializes in manufacturing Aluminum, Zinc, and Lead die casts through HDPC.

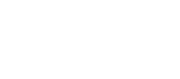

This process is used for metals such as zinc and lead. The injection system of a hot chamber machine is immersed in the melting furnace’s molten metal bath. Metal is forced through the nozzle and into the die as the shot plunger moves.

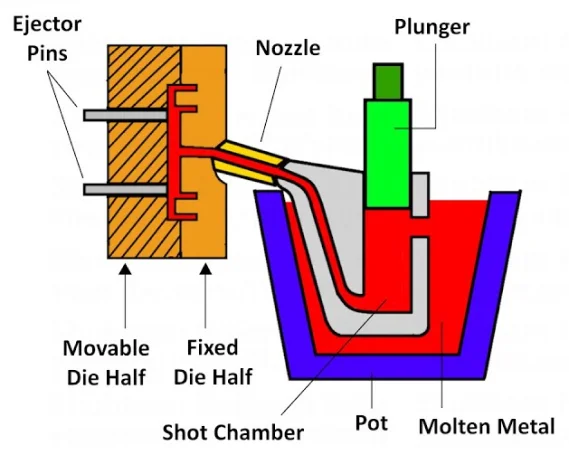

The cold chamber casting process is used for metals such as Aluminum and brass. The molten metal is poured into a port of the cold chamber sleeve, either manually or automatically. A hydraulically driven plunger moves through the steel sleeve, closing the port and driving the metal into the die at high speed and pressure. After the casting has solidified, the plunger is withdrawn, the die is opened, the casting is expelled, and the system is ready for the next shot cycle.

The applications of high-pressure die casting are vast and varied, ranging from the automotive and aerospace industries to the medical and electronics sectors.

Automotive Parts

Transmission Cases

Pneumatic components

Electrical Equipment

We ensure superior quality for products across Industries.

At Marcus, we have well-equipped manufacturing units and a team of skilled professionals with 40+ years of experience in high-pressure die casting. Our capabilities include the following –

Precision machining ensures that it meets the required tolerances and specifications.

We offer a range of secondary operations, including sub-assembly, trimming, leak testing, polishing, and plating, to provide a complete solution for your manufacturing needs.

Our rigorous process ensures that all our products meet industry standards and exceed client expectations.

With our in-house toolroom facilities, we can quickly deliver prototypes in short lead times.

Die casting is a manufacturing process where high-pressure forces molten metal into a mold cavity. The metal cools and solidifies, taking the shape of the mold. The mold is then opened, and the newly formed metal part is ejected.

Marcus has a comprehensive quality control system in place to ensure that all parts produced meet or exceed customer requirements. This includes rigorous testing and inspection throughout the production process and ongoing monitoring and evaluation of quality metrics.

Yes, Marcus can provide custom tooling for die-casting projects. The company has in-house tooling capabilities and can work with customers to design and manufacture custom molds and tooling to meet their specific needs.

Marcus offers a range of design support services for die-casting projects, including design for manufacturability (DFM) analysis, 3D modeling, and prototyping. The company’s team of experienced engineers can work with customers to optimize their designs for the die-casting process and ensure that parts can be produced efficiently and effectively.

In the context of high-pressure die casting, shrinkage refers to the reduction in volume or size of the metal as it cools and solidifies within the die cavity. This phenomenon occurs due to the natural contraction of the metal as it changes from a liquid to a solid state. Shrinkage is a common concern in casting processes, including high-pressure die casting, because it can lead to defects and dimensional inaccuracies in the final product.

High-pressure die casting is a manufacturing process used to produce intricate and complex metal parts with high precision and excellent surface finish. It is commonly employed to create components for a wide range of industries, including automotive, aerospace, electronics, and more.

Key steps in the process include:

High Pressure Die Casting is a precision metal casting process used to produce intricate and complex metal components with excellent dimensional accuracy. This manufacturing technique is widely employed in the automotive, aerospace, electronics, and various other industries.

In this process, molten metal, typically aluminum or zinc-based alloys, is injected under high pressure into a steel mold, also known as a die. The die is specifically designed to form the desired shape of the final product. The application of high pressure ensures that the metal fills all the intricate details of the die, resulting in a finely detailed and precise finished product.

With over 4 decades of experience and crafting products for 100+ brands, we are the perfect partner for die casting.

Tell us your query in detail.