At Marcus, we are dedicated to delivering top-quality mechanical components and assemblies that meet the high standards of the automotive industry. Our focus on manufacturing excellence allows us to create custom die casting solutions for even the most complex automotive applications, including

Marcus is dedicated to providing high-quality mechanical components and assemblies that meet the demanding needs of the healthcare industry. We strive to deliver superior value to our clients by working collaboratively, leveraging our manufacturing expertise and driving innovation through our die casting solutions.

Marcus specializes in manufacturing superior electrical components and solutions. With advanced facilities and a commitment to quality and innovation, our team has the expertise to deliver high-quality die casting solutions that meet your specifications.

At Marcus, we are experienced in manufacturing custom hydraulic systems to meet the specific needs of our customers, whether they require high pressure, high flow, or specialized control capabilities. We use the latest manufacturing processes and technologies to deliver products that perform at the highest level.

We are committed to manufacturing high-quality and reliable pneumatic components and systems. We use the latest manufacturing processes and technologies to deliver products that meet or exceed our customers’ expectations.

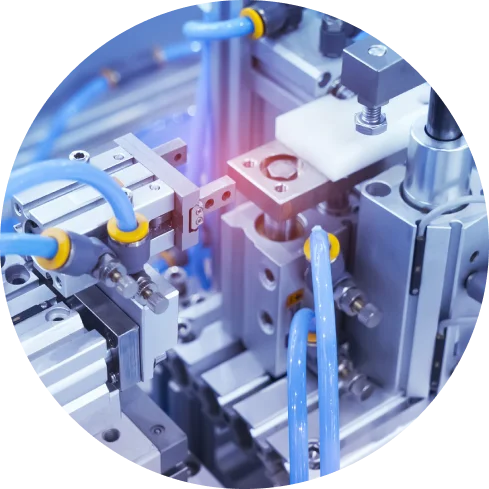

Die casting is a manufacturing process where high-pressure forces molten metal into a mold cavity. The metal cools and solidifies, taking the shape of the mold. The mold is then opened, and the newly formed metal part is ejected.

Several finishing options are available for die-cast parts, including painting, plating, anodizing, and powder coating. These finishing options can help improve the appearance and durability of the parts and provide additional protection against corrosion and wear.

Marcus has a comprehensive quality control system in place to ensure that all parts produced meet or exceed customer requirements. This includes rigorous testing and inspection throughout the production process and ongoing monitoring and evaluation of quality metrics.

Yes, Marcus can provide custom tooling for die-casting projects. The company has in-house tooling capabilities and can work with customers to design and manufacture custom molds and tooling to meet their specific needs.

Marcus offers a range of design support services for die-casting projects, including design for manufacturability (DFM) analysis, 3D modeling, and prototyping. The company’s team of experienced engineers can work with customers to optimize their designs for the die-casting process and ensure that parts can be produced efficiently and effectively.

With over 4 decades of experience and crafting products for 100+ brands, we are the perfect partner for die casting.

Tell us your query in detail.