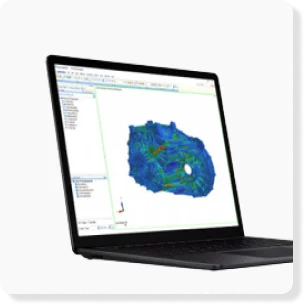

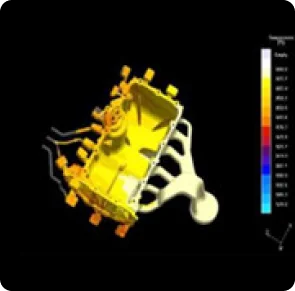

At Marcus, we work closely with the tooling and prototyping team to optimize product quality while utilizing services that include die casting, metal fabrication, zinc alloy casting, and vibro polishing. We rely on advanced design tools and simulation software to guarantee that every project meets the highest standards of precision and quality. Our advanced simulation tools can quickly analyze your design and make any necessary adjustments before moving on to production.

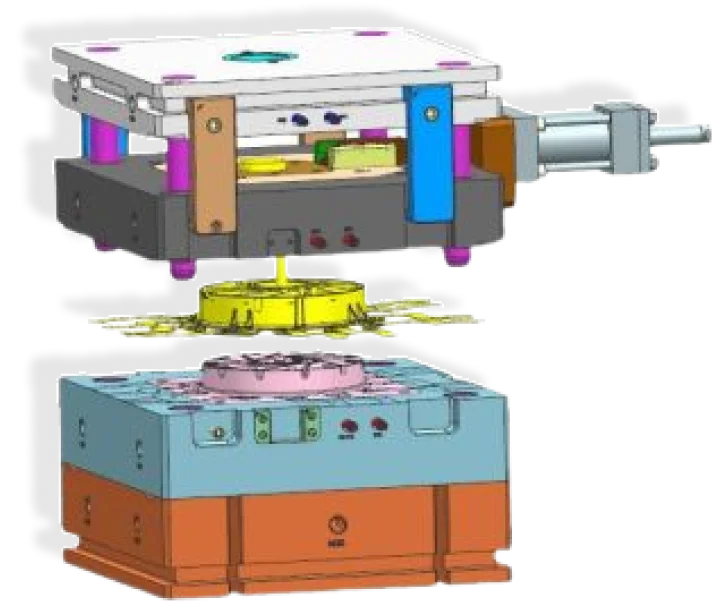

The tool design and simulation process involves creating and testing equipment for precise engineering tasks. This uses computer-aided design (CAD) software and simulation tools to analyze instrument performance before production. By doing so, the final product can be made to be as precise and efficient as possible. Design simulation approaches are now widely used in product development across various industries. Their significance has increased thanks to the availability of faster, more affordable computers and user-friendly software. This allows users to explore new technologies and applications with ease. Tool design and simulation can be used in the automotive, aerospace, medical, and consumer goods industries.

Tool design and simulation is the process of designing and simulating the production of tools and parts using computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This process has a wide range of applications in the manufacturing industry, including:

Efficient Design Optimization

Virtual Prototyping

Minimization of Errors

Product Analysis

We ensure superior quality for products across Industries.

At Marcus, we have well-equipped manufacturing units and a team of skilled professionals with 40+ years of experience in high-pressure die casting. Our capabilities include the following –

Precision machining ensures that it meets the required tolerances and specifications.

We offer a range of secondary operations, including sub-assembly, trimming, leak testing, polishing, and plating, to provide a complete solution for your manufacturing needs.

Our rigorous process ensures that all our products meet industry standards and exceed client expectations.

With our in-house toolroom facilities, we can quickly deliver prototypes in short lead times.

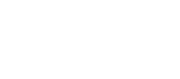

Die casting is a manufacturing process where high-pressure forces molten metal into a mold cavity. The metal cools and solidifies, taking the shape of the mold. The mold is then opened, and the newly formed metal part is ejected.

Several finishing options are available for die-cast parts, including painting, plating, anodizing, and powder coating. These finishing options can help improve the appearance and durability of the parts and provide additional protection against corrosion and wear.

Marcus has a comprehensive quality control system in place to ensure that all parts produced meet or exceed customer requirements. This includes rigorous testing and inspection throughout the production process and ongoing monitoring and evaluation of quality metrics.

Yes, Marcus can provide custom tooling for die-casting projects. The company has in-house tooling capabilities and can work with customers to design and manufacture custom molds and tooling to meet their specific needs.

Marcus offers a range of design support services for die-casting projects, including design for manufacturability (DFM) analysis, 3D modeling, and prototyping. The company’s team of experienced engineers can work with customers to optimize their designs for the die-casting process and ensure that parts can be produced efficiently and effectively.

Our experienced team will contact you soon. Submit your requirement or raise an inquiry.

Tell us your query in detail.