In the rapidly changing manufacturing industry, businesses continually seek innovative approaches to enhance productivity, streamline operations, cut costs, and maintain quality standards. Die casting is a standout performer in manufacturing, surpassing sandblasting in versatility and advantages.

Die casting, known for its versatility and precision, produces intricate components accurately and consistently, making it essential in the automotive, aerospace, and electronics industries. Moreover, die casting excels in optimizing material usage, reducing waste, and minimizing the need for extensive post-processing. It is an environmentally responsible choice, aligning with the growing emphasis on sustainable manufacturing practices.

Let’s explore the various advantages of die casting.

Advantages of Die Casting in Modern Industry Applications

Die casting is a crucial process across various industries, from automotive to agriculture and mining, with multiple benefits such as:

Precision and Dimensional Accuracy

Die casting produces components with high precision and dimensional accuracy. It is used in fabricating complex and internal machine parts that require high precision and accuracy, crucial in the automotive and aerospace industries.

High Production Efficiency

Die casting helps to manufacture a high volume of components in a limited time due to its fast cycle times. Die casting increases production efficiency and is useful for agricultural, construction, and mining machinery industries.

Complex Geometries

Die casting enables manufacturers to achieve metal components with intricate and complex geometries essential for applications like electronic housings, gear cases, pumps, valves, connectors, brackets, and more.

Material Versatility

Die casting can be used with a variety of metals and alloys, like aluminum, zinc, magnesium, copper, and more, allowing manufacturers to choose materials that suit their requirements in terms of strength, durability, and other properties that are essential in the agricultural, aerospace, and automotive industries.

Strength and Durability

Die casting uses durable alloys such as aluminum, magnesium, or zinc, which allows exceptional strength and durability. These alloys show high corrosion resistance, ensuring the components withstand the demanding environments and function reliably.

Cost-Effective Mass Production

Die casting can manufacture a high volume of components in a short time due to its fast cycle, which results in a relatively low cost per unit. This is advantageous for the agricultural, construction, and mining machinery industries.

Types of Die Casting and Their Advantages

1. High-Pressure Die Casting (HPDC)

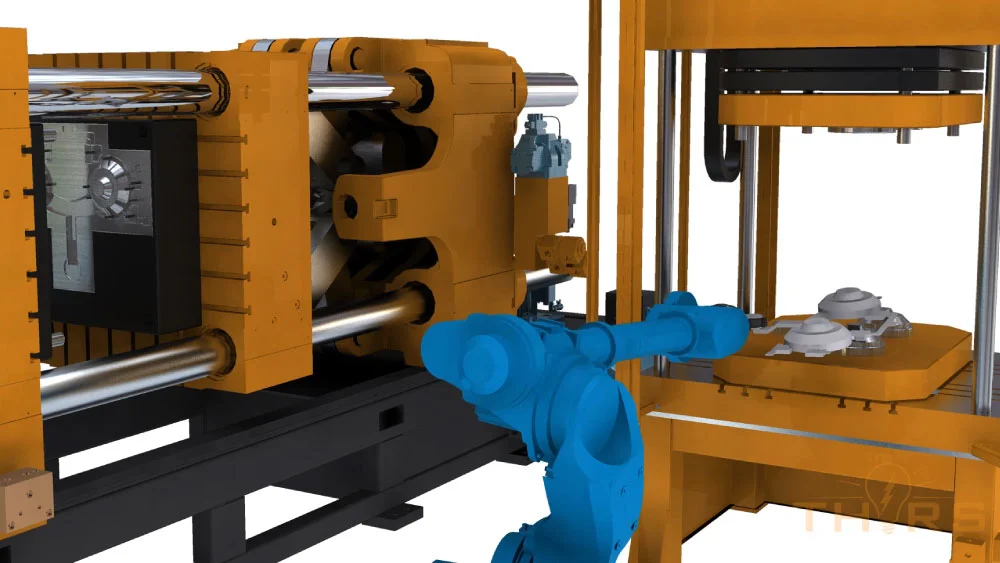

High-pressure die casting suits non-ferrous metals like aluminum, zinc, magnesium, and copper. This process involves injecting molten metal into a precision-designed mold at high pressure into a closed steel die cavity.

Advantages

The advantages of high pressure die casting are:

Complex Geometries

High-pressure die casting is well-suited for creating parts with intricate and complex shapes, including thin walls, fine details, undercuts, and internal features crucial for the automotive and aerospace industries.

Material Versatility

High-pressure die casting can work with various metals and alloys, including aluminum, zinc, magnesium, and others, making it suitable for multiple applications in different industries.

High Surface Finishing

It helps produce components with a smooth surface finish as the high pressure helps the molten metal flow evenly into the mold cavity, reducing the need for extensive post-processing like polishing or grinding.

Reduced Material Waste

Die casting minimizes material waste by recycling excess metal from the casting system. This sustainable approach aligns with modern environmental concerns and reduces material costs.

2. Hot Chamber Die Casting

Hot Chamber Die Casting is only suitable for alloys having low melting points, like lead, tin, zinc, and a few magnesium alloys. In this, an alloy is melted in a furnace within the equipment. This process offers a longer tool life and requires minimum safety measures.

Advantages

The advantages of hot chamber die casting are:

Faster Cycle Times

Hot chamber die casting has a relatively shorter cycle time than cold chamber die casting, making it suitable for high-volume productions in a short time.

High Precision

Hot chamber die casting can produce exact, intricate, complex parts with tight tolerances. This makes it suitable for applications where precision and consistency are critical.

High-Quality Parts

Hot chamber die casting produces parts with excellent surface finishing because the molten metal is injected into the die at high pressure, ensuring that the mold is filled with molten metal evenly and uniformly.

Cost-Effective

The process requires minimal tooling, meaning the initial investment is low for the long term. Additionally, hot chamber die casting produces little to no waste, which reduces material costs.

3. Cold Chamber Die Casting

Cold chamber die casting handles alloys with high melting points and corrosive properties like aluminum and zinc alloys, brass, and copper. The metal is liquefied in a high-temperature furnace and then dipped into a Cold Chamber infiltrated into the die.

Advantages

The advantages of cold chamber die casting are:

Used for High Melting Points and Diverse Metals

The cold chamber die casting method uses metals with high melting points, such as aluminum, copper, brass, and zinc, that help produce diverse metals with different properties.

Reduced Material Waste

Cold chamber die casting minimizes material waste by recycling excess metal from the casting system. This environmentally responsible approach aligns with modern sustainability and eco-friendly manufacturing practices.

Production Efficiency

This process is soundest for high-volume production due to its quick cycle times. It can produce a large number of parts in a short amount of time. This results in cost and time savings in large-scale manufacturing companies.

Cost-Effective for Large Companies

The initial tooling costs can be high, but it becomes cost-effective when producing large quantities due to its high-speed production abilities, translating to economies of scale and reducing the cost per part when making large amounts.

4. Gravity Die Casting

In gravity die casting, a liquid metal is poured into a metallic mold without external force. It utilizes the force of gravity to facilitate the metal’s flow into the mold. It is commonly used in automotive, aerospace, and electronics industries, where high-quality, complex components.

Advantages

The advantages of gravity die casting are:

Tight Tolerances and Dimensional Accuracy

Gravity die casting can achieve tight tolerances and high dimensional accuracy, ensuring that parts fit together precisely and perform as intended. It is suitable for applications where precise component alignment is critical.

Reduced Porosity

The controlled mold filling in gravity die casting reduces the likelihood of porosity or air pockets within the casting. This is essential in applications that require parts with high structural integrity and resistance to leakage.

Material Versatility

Gravity die casting can be used with various materials, including aluminum, zinc, and some copper alloys, allowing manufacturers to select materials that best suit the specific requirements of their applications.

Excellent Surface Finish

Gravity die casting typically produces parts with a smooth surface finish, valuable in industries where aesthetics and surface quality are essential, such as automotive, decorative hardware, and consumer electronics.

Also Check: Types of Die Casting Processes Offered by die casting Suppliers in India

Conclusion

In conclusion, die casting has numerous advantages, from high dimensional accuracy to increased production efficiency; it has firmly established its place in modern industry, evolving needs and demands of various sectors, from automotive and aerospace to electronics and consumer goods.

By teaming up with a suitable die casting supplier, manufacturers can obtain high-quality components that are precise and reliable for their projects. One dependable partner is Marcus Hi-Tech Engineering, renowned for their innovative die casting techniques and exceptional outcomes.

FAQs

Die casting is a manufacturing process that involves injecting molten metal into a mold to create precise, complex, and high-quality parts. Its advantages include excellent dimensional accuracy, high production efficiency, and the ability to create intricate shapes.

Die casting can be used with various metals, including aluminum, zinc, and magnesium. The choice of material depends on the specific requirements of the part being produced.

Aluminum die casting offers several advantages, including lightweight parts, excellent corrosion resistance, good thermal conductivity, and the ability to produce thin walls and complex geometries.

Compared to other methods like machining or forging, die casting typically requires less post-processing, resulting in cost savings and faster production times. It also offers better material utilization.